Prospective projects

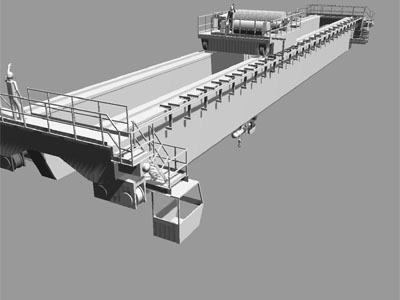

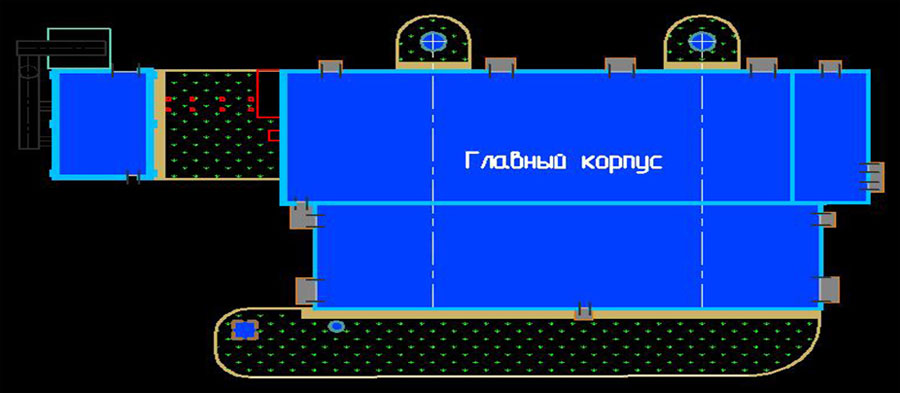

Gas turbine combined cycle power plant project

Gas turbine combined cycle power plant project is a modem and economical process system, allowing the most efficient utilization of metallurgical industry secondary gases to satisfy enterprise’s need in electrical power.

The institute together with some partner organizations has developed a project and detail documentation for the construction of a 2x151.5 MW gas turbine combined cycle power plant, first in CIS, for one of the largest enterprises in Ukraine – OJSC "Alchevsk Iron and Steel Works" (units startup in 2010 and 2011).

Each power unit consists of the following gas and steam turbine equipment:

- Gas turbine, gas compressor, steam turbine, generator (all by Mitsubishi, Japan);

- Heat recovery steam generator made as per design of Nooter/Eriksen company, USA;

- Steam turbine condenser (UBA, USA).

Metallurgical industry secondary gases, i.e. low calorific BFG and LDG gases mixture enriched by adding COG, shall be used as fuel.

Advantages:

- Considerable reduction of natural gas consumption and, as a result, considerable reduction of prime cost of the production to be issued;

- Considerable reduction of contaminants emission to the atmosphere (including carbon dioxide) and improvement of the environment in the works.

The institute is ready to design a project of the same GT CCPP in the shortest terms.

As per Customer’s wish, design documents can be made using

3-D PDMS system.

Auxiliary cogeneration plants projects

Cogeneration plants, intended for joint production of electrical and heat power, are the most up-to-day and effective technological systems of power supply.

Institute has developed the project for construction of the 2x12.9 MW auxiliary cogeneration plant for CJSC "Severodonetsk association "AZOT"" – one of the biggest Ukraine chemical enterprises.

The following economical and safety equipment was used:

- Gas turbine generator SGT – 400 (Siemens – "Lincoln", Great Britain);

- Gas compressor 4GM2,5-6,6/9-23C (OJSC "Sumi Frunze plant, Ukraine");

- Heat-recovery steam generator "Condor" (Standartkessel, Germany).

Natural gas is used as fuel, which is supplied from existing integration net.

Advantages:

- Electrical and heat power of cogeneration plant allows replacing of equivalent power quantity at 100%, supplied from power system and steam quantity at 50%, supplied from works HPP for acetic acid shop needs;

- Cogeneration plant implementation will allow sufficient increasing the acetic acid shop power supply, ensure contaminants emission reduction to atmosphere and improve the environment at enterprise.

The institute is ready to design a project of the same cogeneration plant project in the shortest terms. As per Customer’s wish, design documents can be made using 3-D PDMS system.

Русский

Русский English

English Українська

Українська